Selecting the right packaging manufacturer is crucial for ensuring product quality, cost efficiency, and brand reputation. Below are key factors to consider when making this decision:

Guangdong Lebei Packing Co.,Ltd, was founded in 1995 with over 150 workers, have been committed to production and sales of all kinds of flexible packaging with self-support import and export right.

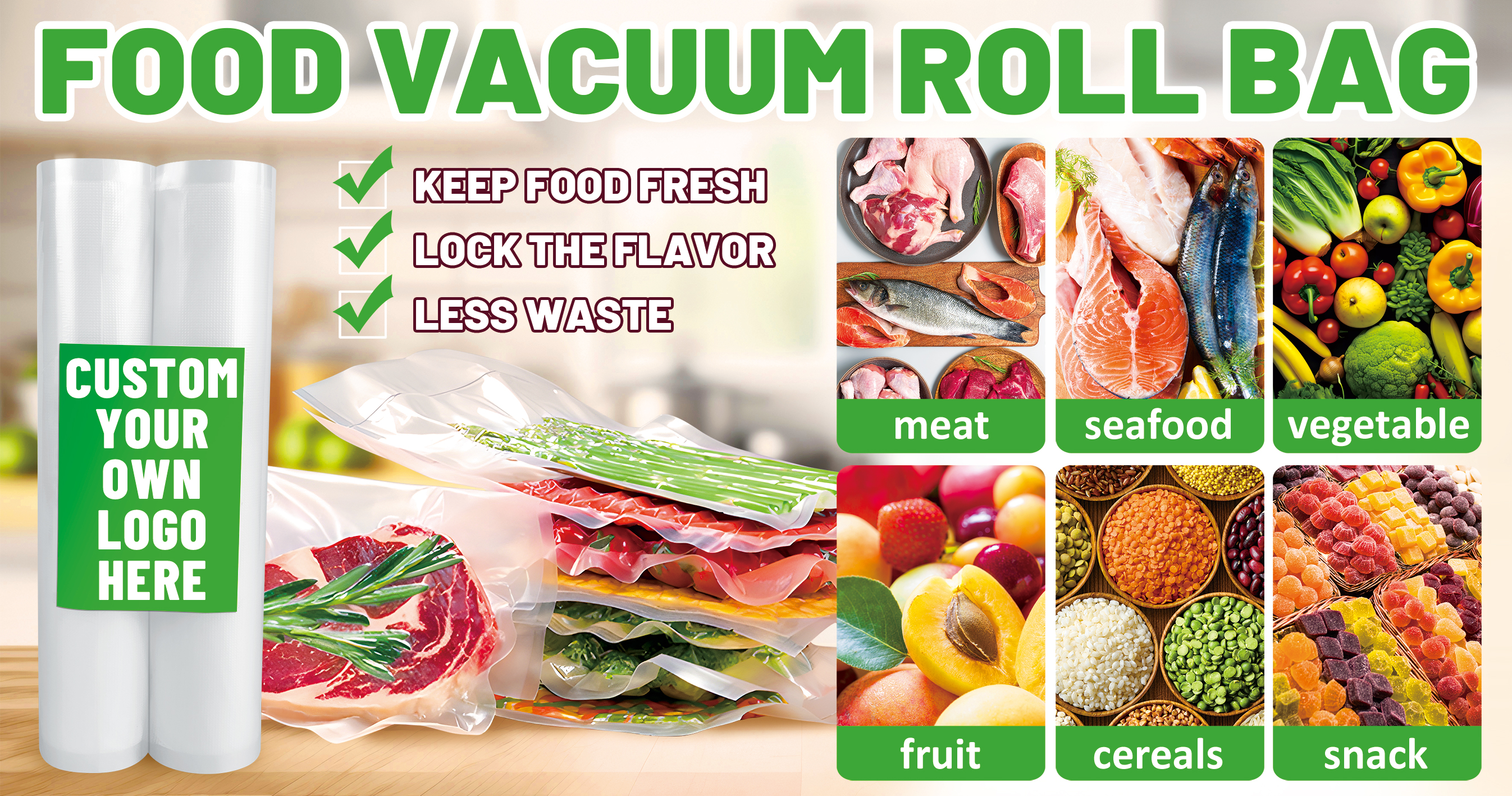

The company mainly products include ready to ship pouch, stand up pouch, flat bottom pouch, three/four side seal pouch, back side seal pouch, spout bags, roll film, kraft paper pouch, coffee bags, tea bags, daily necessities packaging bags, etc.

Lebei Packing has advanced production equipment including the latest northern electronic shaft printing machine, the printing online off-line testing machine, solvent free composit machine, multi-function bag making machine and etc.

Lebei Packing have more than 100 patents available to meet the diverse needs of our customers, and passed QS, SGS, HACCP, BRC, ISO certification.

With solid overall strength, we have 8 branches in domestic, such as famous branch: HUIXING, ENLEMEI, RENHE, DAER, FEIYANG, NANFANG…

The company always uphold the principle of quality and reputation first. Lebei Packing products are sold to all over the word, for example, Southeast Asia, Middle East,Europe, North America, South America, Africa countries…

Welcome to inquiry. We will the right partner you are looking for.

1. **Quality and Compliance**

Prioritize manufacturers with certifications (ISO, HACCP,e.g.) and a proven track record of delivering durable, defect-free packaging. Request samples to evaluate materials, print quality, and structural integrity.

Our company Guangdong Lebei Packing Co.,Ltd has passed QS, SGS, HACCP, BRC, ISO certification

2. **Customization Capabilities**

Ensure the manufacturer offers tailored solutions to meet your unique needs, such as custom designs, sizes, or sustainable materials. Flexibility in adapting to your brand’s vision is essential.

3. **Production Capacity and Lead Times**

Assess their ability to scale production according to your demand. Reliable manufacturers provide clear timelines and contingency plans to avoid delays during peak seasons.

we are able to produce packaging bags over 60,000,000pcs per month, and roll film more than 500 tons per month

4. **Cost Efficiency**

Compare quotes, but avoid compromising quality for lower prices. Look for transparent pricing models and inquire about bulk discounts or long-term partnership benefits.

5. **Sustainability Practices**

Partner with manufacturers committed to eco-friendly materials (recyclable, biodegradable,e.g.) and energy-efficient processes. Sustainability aligns with modern consumer expectations and regulatory trends.

6. **Communication and Support**

Choose a responsive team that values collaboration. Effective communication ensures smooth problem-solving, from prototyping to final delivery.

Wechat/WhatsApp:+86-15816539431

Email:sales10@lbpacking.net

7. **Geographic Location**

Local manufacturers may reduce shipping costs and carbon footprints, while overseas suppliers could offer cost advantages. Weigh logistics against your priorities.

By evaluating these factors holistically, you can identify a packaging partner that enhances your product’s appeal, operational efficiency, and market competitiveness. Always conduct site visits or virtual audits to finalize your decision confidently.

Post time: Mar-05-2025